The so called 4 synchro gearbox was introduced in the Autumn of 1968 and that was a significant upgrade to the Mini driveability. Up until then only 3 synchro gearboxes were available – the first gear is the non-synchromeshed one. In practice, having a 3 synchro gearbox means we need to stop the car in order to engage first gear.

But these old 3 synchro gearboxes still have their place today, mostly on original cars – namely the Cooper S with its famous 22G190 or 22G333 casings – and in my opinion, they’re not really that bad. As long as we remember not to engage first while the car is still moving, a well built 3 synchro gearbox is fine.

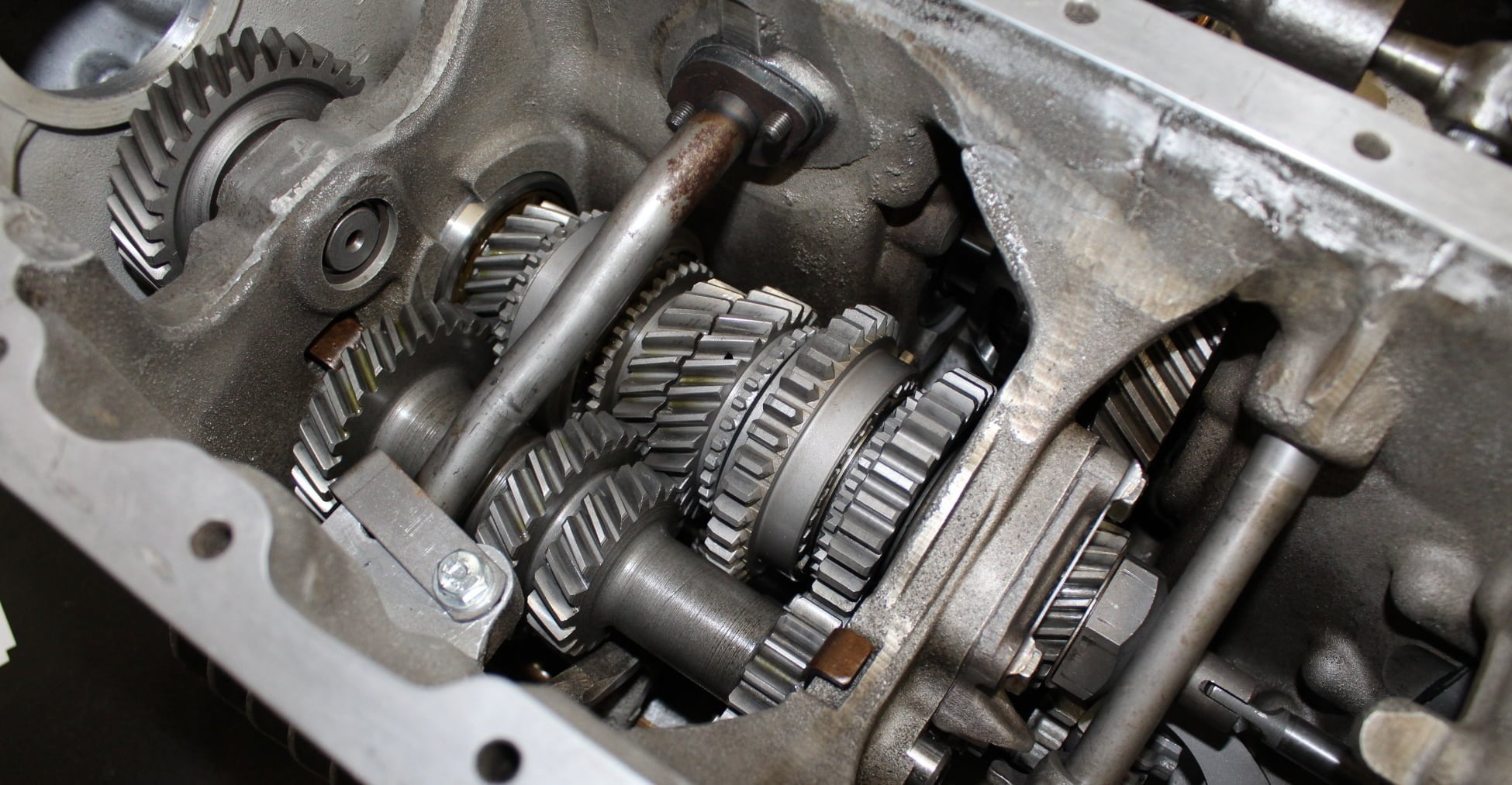

However, not all 3 synchro gearboxes are the same, they were developed and evolved through time. The first Minis, up to 1962, had the cone synchromeshed type of gears. They’re called like that because they had a bronze wedged ring press fitted in 2nd, 3rd and 4th gears that was supposed to bite the synchro hub in order to help matching the speed of the gear train to the speed of the wheels – that’s what makes a gear change smooth. That didn’t work very well because the bronze rings would wear fast and soon enough the gears would start to crunch and being more difficult to change. To improve on that, the A-type gears were introduced with baulk rings. Those are independent rings that work between the synchro hubs and the gears – if they wear, we can replace them. But A-type gears were a bit loud due to the steep angle the helicoidal teeth were cut, so around 1964 the new B-Type gears were introduced and lasted until the 4 synchro boxes were standard in all engines. There were a few more specific changes done through time, but in generic terms these are the 3 types of gears we might find in an early Mini gearbox.

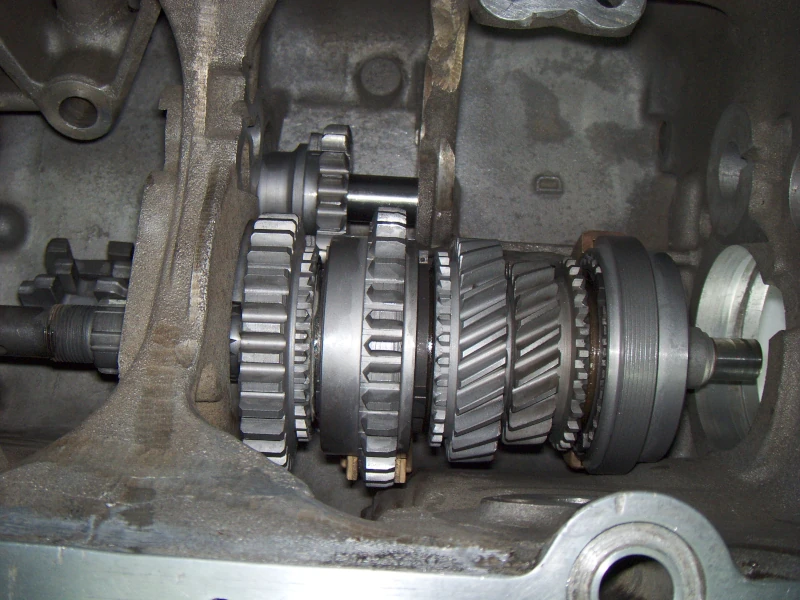

Using a centre oil pick up pipe helps insuring the engine will not get oil starvation on long hard corners, unlike what might happen with the original pick up pipe mounted at one corner. However, when fitting this new part we must check if it fouls the reverse gear, most of the times it will.

To fix this problem we need to bend the pipe until it clears the gear. However, this might only be possible if we grind the web in the casing and enlarge the hole where the pipe goes through.

Here we can see adequate clearance to the reverse gear.

The original 22A145 gearbox from my Mini has cone synchromeshed gears. Those gears are now worn and even if I could replace them, it makes no sense to use that type of gearset when the rest of the engine was upgraded.

Using a later type of 3 synchro gearset in the original casing is not straight forward because this case is machined for the early and smaller double-row bearing. I’ve not gone deep into how to convert the box, but I understand that with some machining it is possible. In this case, it’s just too much work with no real benefit, so instead and since I can’t squeeze a 4 synchro gearset in a 3 synchro gear case, I’ve decided to just use a complete 4 synchro box.

While this decision helps with the reliability and driveability questions, it certainly raises one which is related with the type of gear lever / gear selection mechanism.

All MK1 850cc Minis had “magic wand” gear levers. Those things go straight into the differential housing through a hole in the floors cut next to the footwell. On the other hand, the Cooper and Cooper S models of the same era, had a different type of differential housing where an alloy extension was attached. That allowed the gear lever to emerge between the seats through a hole cut in a different location in the floors – that’s the “remote” type. By 1968, when the 4 synchro boxes were introduced, the same style of remote extension was standardized in all Minis (with the exception of the Van and Pickup models that now had their own specific type of magic wand gear lever).

Being from 1961, my Mini does not have that hole on the floor that allows a remote type gearbox to be used. I could grab a grinder and just open it up, but… I don’t want to. Instead of doing that, I’ll adapt the original 850 magic wand differential housing to a 4 synchro gearbox. Sure I could get the Van / Pickup conversion, but that would be too easy, wouldn’t it?

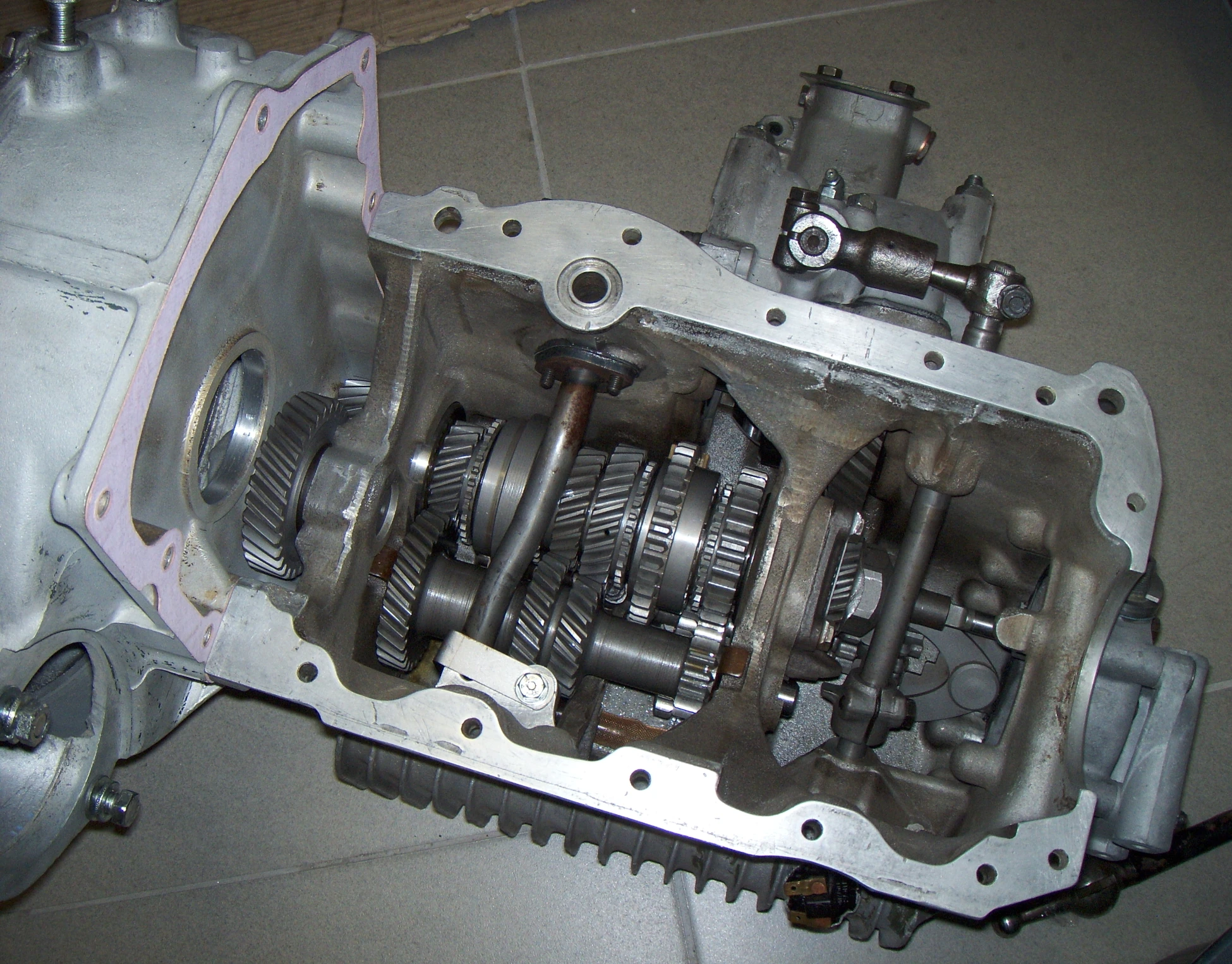

The truth is I had a few of these early 4 synchro cases (22G1128) around and after a quick inspection the one that looked better, with no broken fins and less play in the layshaft locating holes, didn’t have any differential cover attached to it. It only made sense I looked for a 3 synchro cover to fit.

Swapping Mini differential covers is not recommended because originally both case and cover get the diff bearings holes machined at the same time, as if they were one single piece. Both holes are machined inline and when we swap a cover to another case most often we can feel a lip where both parts meet. Sometimes we can improve on that by removing the locating dowels which then allows for some adjustment, but the true test is to indicate the circunference for each bearing hole. We might find that we don’t feel any lip, but the holes are way out of round because the parting line between cover and case is just in a different place. To sort this, either we’re very lucky or we need to re-machine both parts to make them a matched set.

I was lucky enough to find one cover that fitted perfectly, even with the dowels. I had 7 to choose from and only one was a good match.

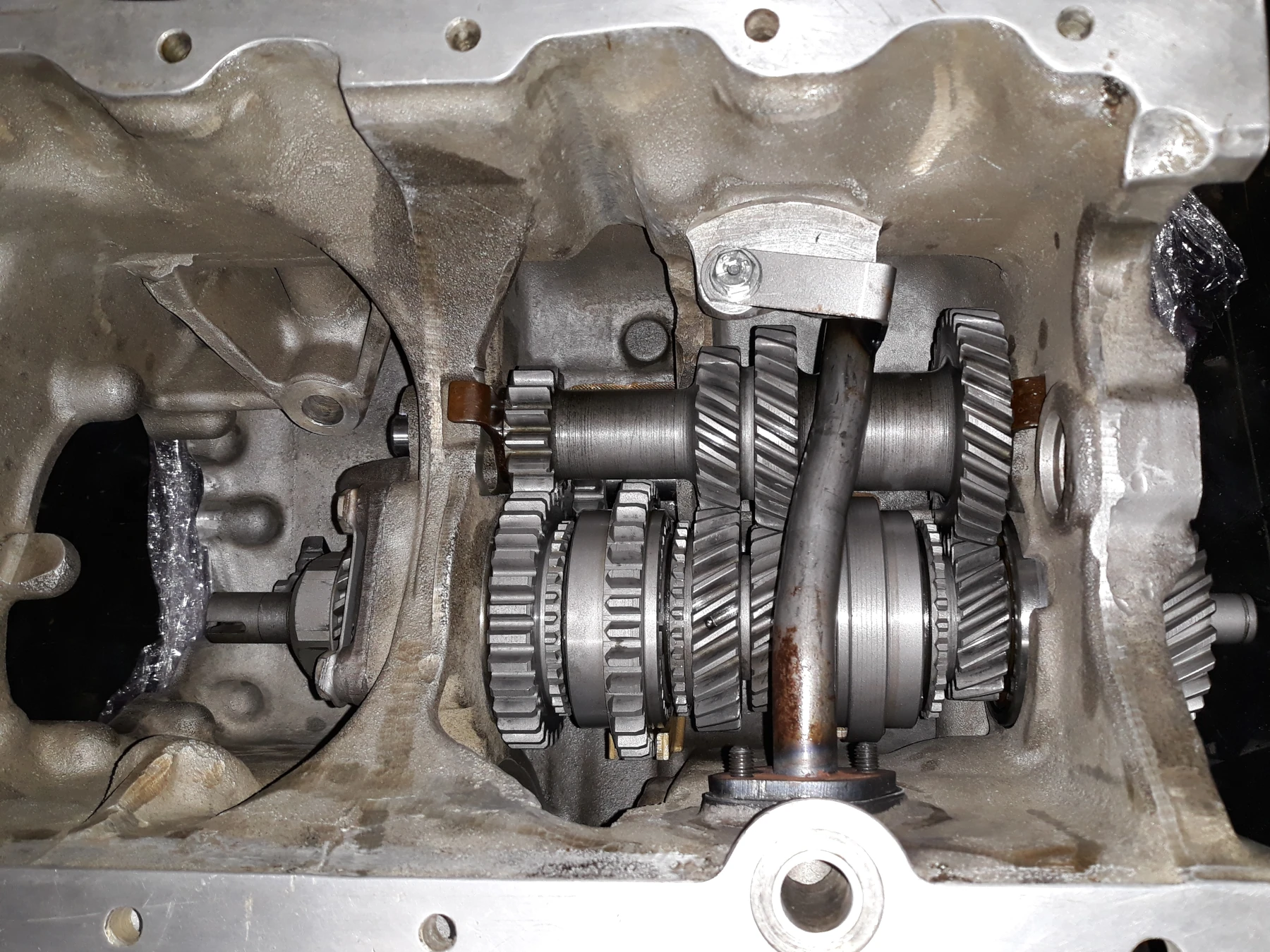

This specific gearbox I’m using was not originally from a Mini, but from an Austin 1300GT and the cool thing about it is that the gear cluster is the same used in the MK2 Cooper S. The difference from the normal set that can be found in all other Minis of the same era is “just” the laygear (22G1040) and the first motion shaft which has 18 teeth instead of the usual 17, but both these parts make up the “close ratio” upgrade, so that will be interesting to test in this engine.

The final ratio chosen was 3.44:1, that seems to be a good all-around compromise. The new magic wand differential cover went on easily, all bolts for the side covers aligned well, no issues there.

The speedo gears however, were a different subject. I tried to calculate the correct speedo gears I should use knowing the wheels and tyres, the full gearbox specification and that the original speedo with white background will be maintained. According to my math the closest set of worm/pinion gears that suits this car is TXD10006 (pinion) and TXF10004 (7 tooth worm gear) – this is the set used on export models of the SPI with 3.2 final ratio. And boy, were those hard to find!

Another addition to this box is a Lucas reverse light switch. I’m still deciding if I’ll be using a reversing light, but the switch is already there and working, just in case I go forward (or should I say backwards) with it.